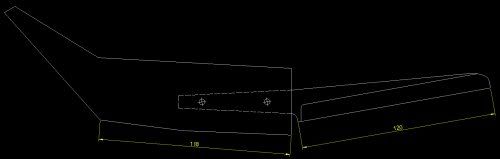

Well im fancying having ago at a North american indian crooked knife

any body got any info in specs etc (yeh yeh i know all hand made to no drawings etc

etc (yeh yeh i know all hand made to no drawings etc  )

)

found this artical

with interesting pictures

was going to try 3mm thick maybe grind it down to 2.5 ish ?? and 20deg single bevel

Oh ia have been looking up Jojos old threads on his

any feed back on hollowing with the bevel on the inside of the curve ?? as spoon knifes usually are beveled on the outside to make it easier to turn

ATB

Duncan

any body got any info in specs

etc (yeh yeh i know all hand made to no drawings etc

etc (yeh yeh i know all hand made to no drawings etc  )

)found this artical

with interesting pictures

was going to try 3mm thick maybe grind it down to 2.5 ish ?? and 20deg single bevel

Oh ia have been looking up Jojos old threads on his

any feed back on hollowing with the bevel on the inside of the curve ?? as spoon knifes usually are beveled on the outside to make it easier to turn

ATB

Duncan

Last edited: